Sand casting is a versatile and widely used metal casting process that involves creating a mold from a mixture of sand and a binding agent, allowing for the production of complex shapes and large components. This method is ideal for both small and large scale production runs, making it a popular choice across various industries, including automotive, aerospace, and manufacturing. The process begins with the creation of a pattern, which is then embedded in a sand mixture to form a mold. Once the mold is prepared, molten metal is poured in and allowed to solidify, after which the sand is removed to reveal the finished casting. Sand casting is favored for its ability to accommodate a wide range of metals and alloys, including ferrous and non-ferrous materials, and it offers excellent design flexibility, making it suitable for intricate geometries. Additionally, the relatively low cost of materials and tools, along with the ability to quickly produce molds, contributes to its efficiency and effectiveness for both prototype development and high volume production. Our foundry is equipped with state-of-the-art technology and skilled personnel to ensure that every sand casting meets the highest quality standards, delivering durable and precise components tailored to our client's needs.

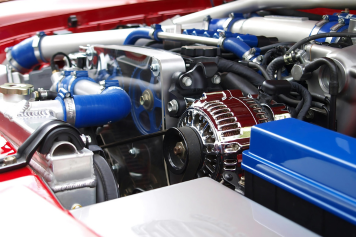

Our foundry specializes in sand casting, providing high-quality components for the automotive industry. With precision and durability, we help drive innovation in design.

Our foundry delivers sand casting solutions for the aerospace industry, ensuring lightweight, components. We prioritize precision and reliability to meet the demands engineering.

Our foundry provides sand casting solutions in marine applications,resistant components for environments. We focus on durability to support the safety of vessels.

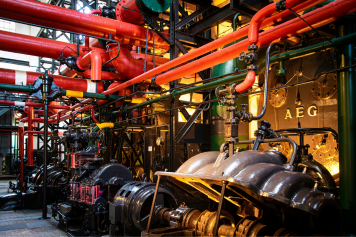

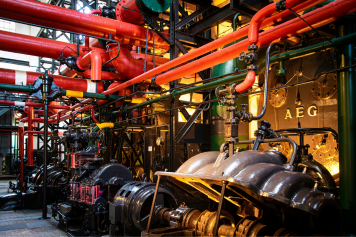

Our foundry specializes in sand casting for the oil and gas industry, producing robust components designed to withstand extreme conditions. We ensure precision and reliability to enhance the efficiency and safety of energy operations.

Our foundry offers sand casting solutions for industrial machinery, delivering durable components that enhance performance. We prioritize quality and precision to meet the demanding needs of various manufacturing applications.

Our foundry provides sand casting solutions for consumer products, ensuring high quality components that combine aesthetics and functionality. We focus on precision and versatility to meet the needs of modern consumer markets.

Ensuring high quality castings in sand casting involves a combination of meticulous techniques and stringent quality control measures. Our foundry employs advanced simulation software to optimize mold design and casting processes, reducing the likelihood of defects. We use high quality, well graded sand to create molds ensure excellent surface finish and dimensional accuracy. Regular testing of sand properties, such as grain size and moisture content, is conducted to maintain consistency in casting quality. Our skilled technicians meticulously inspect stage of the casting process, from mold preparation to the final product, ensuring that all components meet or exceed industry standards.

At KSP Foundry, we are committed to sustainability and actively seek to incorporate eco friendly materials in our sand casting processes. By utilizing recyclable and biodegradable sand systems, we minimize waste and reduce our environmental footprint. Our proprietary sand mixtures are designed to be reused multiple times, significantly decreasing the need for new materials and promoting a circular economy. Additionally, we source binders that are low in volatile organic compounds (VOCs), ensuring a safer working environment while maintaining excellent performance characteristics. Our commitment to using eco-friendly materials extends beyond sand, we also focus on sustainable practices in our operations, such as energy efficient melting techniques and recycling scrap metal. By prioritizing these environmentally conscious choices, we not only enhance the quality of our castings but also contribute positively to the health of our planet, aligning with our mission to deliver innovative solutions that meet the needs of clients.